You’ve heard of Paint Protection Film or PPF as a way to protect your car’s finish from the scratches and blemishes caused by road debris, dirt and bug splatter, so let’s look at exactly what PPF is and how it works.

What Is Paint Protection Film

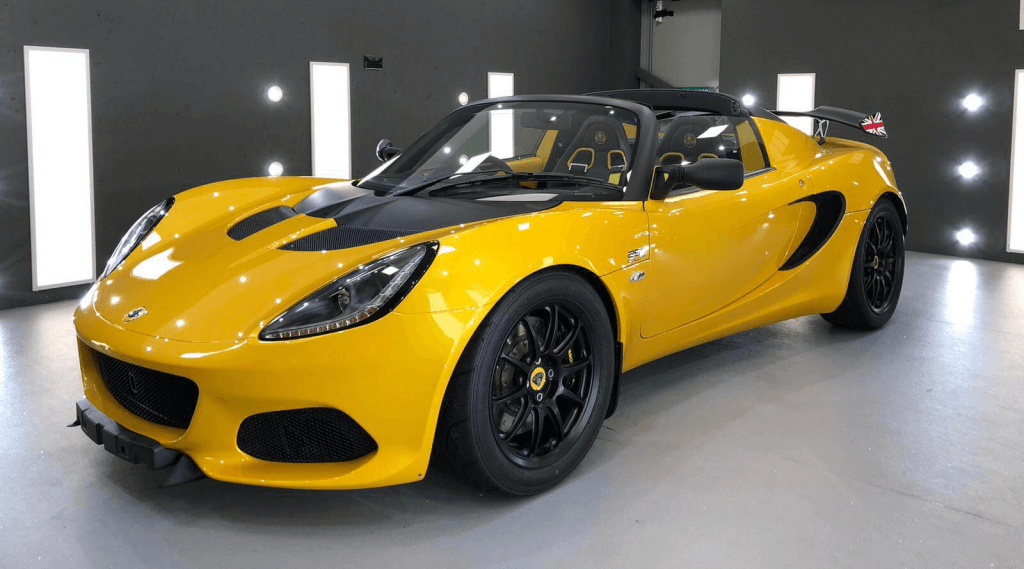

The XPEL paint protection film installed by the XPEL-trained and accredited professionals at Bespoke Detailing Solutions is an invisible polyurethane film applied directly onto the paintwork of a vehicle. It can be clear or coloured as required and serves as a self-healing layer of protection to preserve the lustre of the vehicle’s paintwork.

The XPEL PPF can be applied as a full cover wrap over the entire vehicle, or just across high impact areas that are particularly prone to damage from road debris or other environmental damage.

It is not just a sacrificial layer of protection though, as the self-healing properties of the polyurethane mean it will close-up scratches and realign dents, continuing to protect even after sustaining damage.

How Paint Protection Film Works

The film is made with a special elastomeric polymer technology that gives it a rubber-like elasticity to absorb the energy from the likes of splattering road debris. It is also this elasticity that enables the protective film to heal itself from damage.

The industry standard bearer is XPEL PPF which is crystal clear and will not peel, crack or blister-like lesser quality protective wraps are prone to. It will also not turn yellow over time as inferior versions can, as XPEL PPF always maintains its original clarity so the car’s finish remains immaculate. Another advanced feature of XPEL is that it is completely safe to remove from factory paint, even years after being applied.

To fit each vehicle, precision templates from an extensive database are used to computer-cut a wrap or section of film to fit a specific model or part of a vehicle. It is then bonded to the paintwork, with some long-lasting options providing up to a decade’s worth of protection.

How the PPF Process Works

At Bespoke Detailing Solutions, we always begin with a free consultation where we will review the vehicle, speak with the customer regarding their requirements, and then identify the most suitable and cost-effective PPF package.

Once we know what PPF package the customer requires, we find the make and model of the customer’s vehicle on the database of our PPF software. The database contains an extensive list of the various dimensions of vehicles as provided by their manufacturers, and we use this to determine exactly how much of the PPF will be needed for each installation. The software is linked to a special printer which then produces the pieces of protective film, measured and cut to the exact dimensions of the customer’s vehicle.

The XPEL paint protection film can now be peeled and applied to the vehicle, with each piece installed one at a time via the computer-matched locations. Once the film is properly installed, a settling period is recommended to let the film become 100% bonded, after which the vehicle is fully protected.

To find out more about our paint protection film or to book a free consultation to discuss your requirements, please contact our team on 07903 105143 or darren@bespokedetailingsolutions.co.uk.

Leave a Reply